Hydrogen

We develop and optimize components and systems for the production, storage, and distribution, as well as for the use of hydrogen as an energy carrier or industrial/chemical feedstock for various applications. From electrolysis to compressed gas systems, cryogenic tank systems, and filling stations, to fuel cell systems (including hydrogen conditioning in vehicles and aircraft), we consider numerous systems along the value chain.

We compare, evaluate, and optimize system topologies as well as operating strategies of hydrogen refueling station systems using model-based design and performance analysis. For this, we leverage component models from TIL Suite and the hydrogen-specific Add-On HydrogenEnergySystems. Some examples of the analyses we perform for our customers are:

In the heavy-duty vehicle sector, there are currently no uniform standards for refueling vehicle storage systems. To determine custom refueling protocols (following SAE J2601 or individual customer requirements), we use the model-based and automated capabilities of our software MoBA Automation.

On behalf of our customers we investigate PEMFC and SOFC systems in detail, drawing on our many years of experience from various customer and research projects.

With our system models we can represent the following subsystems:

Detailed material data models, which are part of our material data library TILMedia, are used to describe gas mixtures with a dynamic mixing ratio. This is the basis for the analysis of fundamental physical effects and dependencies at the component and system level. For example, we consider the following specific aspects:

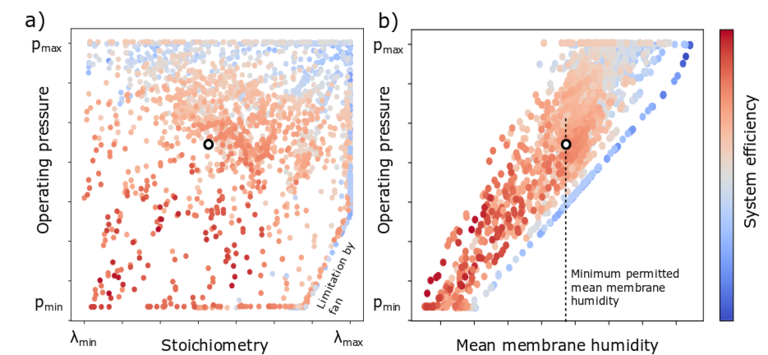

Figure 3: Illustration of exemplary results from a global optimization study to determine the Pareto optimum system efficiency. The optimization parameters are the operating pressure of the stack and the H2 stoichiometry (recirculation). a) Achieved efficiency in the allowable parameter range. The maximum achievable stoichiometry is limited by the maximum speed of the recirculation blower (bottom right). High system efficiencies (red) are achieved in principle at lower pressure and lower stoichiometry. b) Efficiency above the resulting mean membrane moisture. The Pareto optimum found (black circle) lies exactly on the minimum allowed mean membrane moisture, which is an essential constraint of the optimization problem

Power-to-X processes

Power-to-X (PtX) processes can be used to produce synthetic feedstock, fuels, and combustibles from electrical energy. We offer support to customers using such processes with our simulation models. For example, in the context of a high-temperature co-electrolysis in a SOEC/rSOC with subsequent methanation, we use simulation analyses to determine the appropriate composition of the synthesis gas (power-to-syngas) as well as the potential for utilizing heat sources and sinks. For this purpose, we use simplified models of ideal reactors to describe chemical reactions like steam reforming or the water gas shift reaction.

Hydrogen offers promising prospects as a fuel for future low-emission aircraft, both in fuel cells and combusted in classical gas turbines.

With our expertise in modeling and simulation of hydrogen systems in aviation, we support our customers in a wide range of problems:

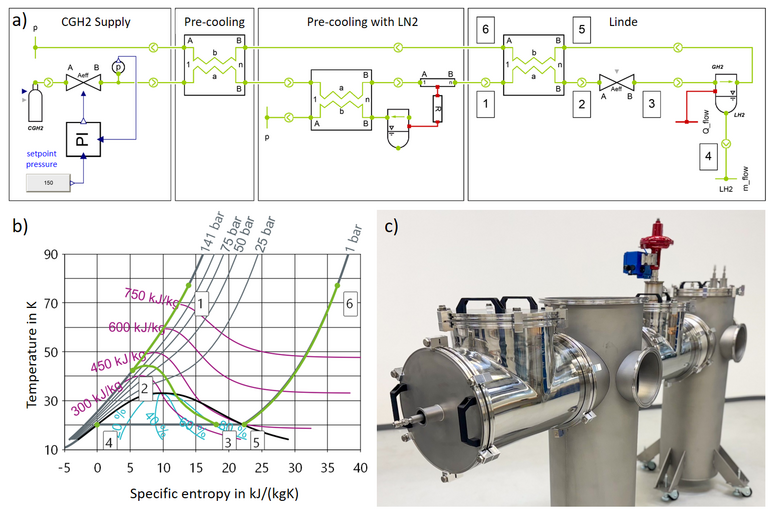

Figure 4: Liquid hydrogen in simulation and measurement: Compressed gaseous H2 is pre-cooled with LN2 and then liquefied using the Linde-Hampson process. a) Flow diagram of a dynamic simulation model of a corresponding H2 liquefaction plant. b) T-s diagram of hydrogen from the simulation of the Linde process for H2 liquefaction. Hydrogen states are visualized at different points along the flow path. c) The installation of the real laboratory facility is also realized by TLK-Thermo.